Anyone who has ever digitized a building knows the pattern: interiors can be captured with mobile LiDAR systems, laser scanners, or 360° cameras. Corridors, technical areas, production halls – all of it can be measured in detail.

But one area is often left out: the roof.

Why Roofs Are Missing – and Why That’s a Risk

The reason is pragmatic. Climbing onto a roof with backpack LiDAR or stationary scanners is cumbersome, requires permits, and is often simply too dangerous. The result: digital models with high interior resolution but incomplete exterior contours.

This is a real problem for facility management and technical operations. Roofs are particularly sensitive, since HVAC systems, solar panels, roof drainage, or leak detection all depend on precise knowledge of the exterior.

A Simple but Effective Approach: Drones

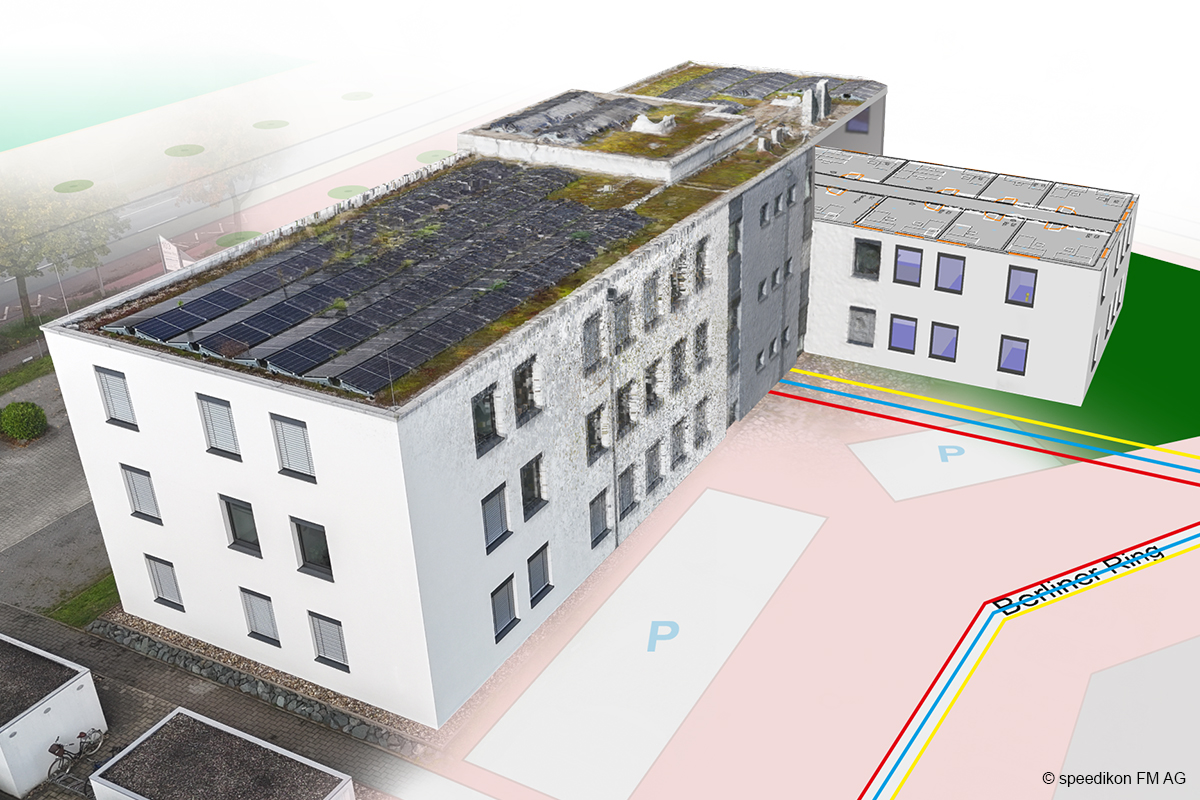

speedikon® VIP solves this problem without exotic hardware. Instead of relying on complicated special equipment, the platform uses drone images and photogrammetry:

- Drones fly over the building and capture high-resolution photos from various perspectives.

- These images are used to create precise point clouds that reconstruct the roof structure All without having to access the roof.

- Exterior models and interior scans are then combined to create a continuous 3D model.

More Safety, Lower Costs, Higher Quality

The approach is not only safer, but also economically scalable. Facility managers receive complete, geometrically reliable models from the basement to the roof. This is ideal for maintenance, condition assessment, renovation planning, or insurance purposes.

What was once laborious and expensive can now be implemented efficiently and safely.

For more information, visit www.speedikonvip.de

Picture: speedikon FM AG