Recent incidents in industrial environments such as the pipeline accident in Brandenburg highlight a recurring issue in asset intensive operations. Safety risks often do not arise because information is missing but because existing information is fragmented and disconnected from physical reality on site.

When operational data is detached from the actual asset it refers to, even experienced teams are forced to rely on assumptions. This gap between geometry and information is where human error begins.

When Data Exists but Context Is Missing

In many industrial organizations, critical information is distributed across multiple systems. Process data such as pressure, temperature, sensor readings or maintenance histories is stored in CAFM, IWMS, ERP or SCADA systems. Geometric information exists separately in CAD drawings, BIM models, GIS maps or point clouds.

To understand a situation, employees often need to switch between systems, search through documents and consult colleagues. Under time pressure, this search and switch behavior becomes a serious risk factor. Knowing that a pipe is under pressure in a spreadsheet is of little value if it is unclear which pipe section this refers to in a complex industrial plant.

Creating a Shared Spatial Reality

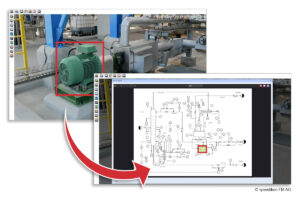

FRAMENCE addresses this challenge by providing photorealistic digital twins that reconnect data with its physical context. Information from different sources can be visualized directly within the spatial representation of the asset, creating a clear link between operational status and real world geometry.

Instead of replacing existing systems, FRAMENCE complements them by adding a photorealistic and spatial layer. The photorealistic digital twin becomes a shared visual reference that helps teams understand where data belongs and how it relates to the physical environment.

Within a browser based environment, FRAMENCE visualizes 3D models, 2D plans, point clouds and image based reconstructions in a coherent and navigable photorealistic digital twin.

Clarity Where It Matters Most

For operators and maintenance teams, this creates immediate situational awareness. Standing in front of a pipeline or technical component, they can use the photorealistic digital twin to clearly identify the relevant asset and better interpret operational information such as pressure, flow or inspection status in its correct spatial context.

This shared visual understanding improves collaboration between operations, maintenance and safety teams. Decisions are no longer based on assumptions but on a common and spatially anchored view of the situation.

From Visualization to Safer Operations

By visually linking operational information with physical geometry, FRAMENCE helps reduce human error, supports maintenance and planning tasks and contributes to safer operations. Complex technical environments become easier to understand and easier to manage directly at the asset itself.

Would you like to see how photorealistic digital twins work in practice with FRAMENCE?

Book a non binding FRAMENCE demo and explore what FRAMENCE can do for your assets.

Picture: Framence GmbH