Risk management in industrial environments is becoming increasingly complex. Facilities must meet strict requirements, operate under high performance expectations, and remain resilient in the face of disruptions. To achieve this, companies need a continuous understanding of the condition of their assets — not just through reports or occasional inspections.

FRAMENCE supports this approach by creating a photorealistic, interactive digital representation of real-world facilities and linking it with operational data. This gives teams a clear, easily accessible overview of their environment at any time.

A Digital Model That Matches Reality

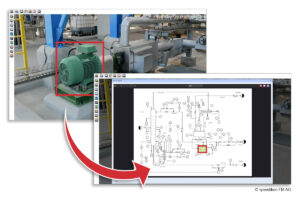

FRAMENCE combines photographs from standard digital cameras into millimeter-accurate, photorealistic, and true-to-scale 3D representations of real-world environments. Depending on the application, smartphone photos, videos, or drone footage can also be used. In addition, further data sources such as laser scans, CAD data, 3D models, plans, live values, and information from third-party systems can be integrated into FRAMENCE and combined into an interactive digital model that precisely reflects the real facility.

Users can move through the digital environment as if they were on-site and access relevant information directly where it matters.

Through this model, teams can:

- Navigate the plant virtually from any location

- Display maintenance data, sensor readings, or risk assessments

- Share information across departments

This creates a continuously up-to-date view of the facility that supports informed decision-making.

From Reactive Processes to Predictive Awareness

Traditional forms of risk management often rely on scheduled inspections, written reports, and separate systems. As a result, early warning signs, such as corrosion, leaks, or blocked access routes can be overlooked.

FRAMENCE extends this approach by enabling a continuous overview of the facility’s condition.

The visual and data-rich representation helps teams to:

- Identify potential hazards at an early stage

- Plan maintenance based on current asset conditions

- Prepare emergency scenarios in a realistic 3D environment

- Visually document audit evidence in a transparent and traceable way

This turns a reactive approach to risk into a proactive, data-supported process.

Operational and Organizational Benefits

With FRAMENCE, companies benefit from noticeable effects on plant operations. Maintenance planning becomes more efficient because actions are based on up-to-date conditions rather than assumptions. Inspections can often be carried out remotely, reducing travel and time requirements. Teams across disciplines reference the same information, improving communication and consistency.

These improvements support a strong safety culture and promote sustainable ways of working.

Understanding Data in the Right Context

FRAMENCE integrates seamlessly with existing IoT, CMMS, and ERP systems.

Operational data, documentation, and process information appear directly at the relevant location within the digital model. This creates a more complete picture of facilities and risks and enables faster, more targeted action.

A New Level of Transparency and Control

With FRAMENCE, companies gain a more comprehensive understanding of their technical environments. The platform supports greater safety, better-informed decisions, and increased resilience in complex industrial settings.

By connecting digital information with the real geometry of the plant, FRAMENCE turns complex structures into clear, actionable insights — enabling teams to recognize risks earlier and manage their facilities with greater confidence.

Contact the FRAMENCE team for a no-obligation demo: https://www.framence.com/demo/

Picture: Frolopiaton Palm/Freepik.com; Edit: speedikon FM AG