In large industrial plants and complex building structures, thousands of machines, cables, control cabinets and valves are in use – many, if not every component, potentially labelled with a barcode or QR code. These markings are intended to enable quick access to technical information. But the reality is often different: Although the QR code leads to a database entry, the information is incomplete, supplementary data is difficult to find or not yet linked to the system at all. The workload for maintenance staff therefore remains high and costs valuable time.

The hurdle: media disruptions and manual searches

Although QR and barcodes are becoming increasingly common in industrial labelling, their use often remains inefficient in practice. Service technicians have to scan codes manually, transfer serial numbers to systems and then search various databases for maintenance histories, spare parts or live data. If the code is not linked correctly or is illegible, time-consuming troubleshooting begins, often with an uncertain outcome. A typical scenario looks like this:

A technician is called to a faulty machine. On site, he looks for the type plate, which is illegible due to dirt and corrosion. The QR code only provides a serial number, but no technical details. Only after switching to a PC and conducting a manual search does the technician receive the required information. This process across various media is not only inefficient, but also prone to errors.

The solution: Automated code recognition

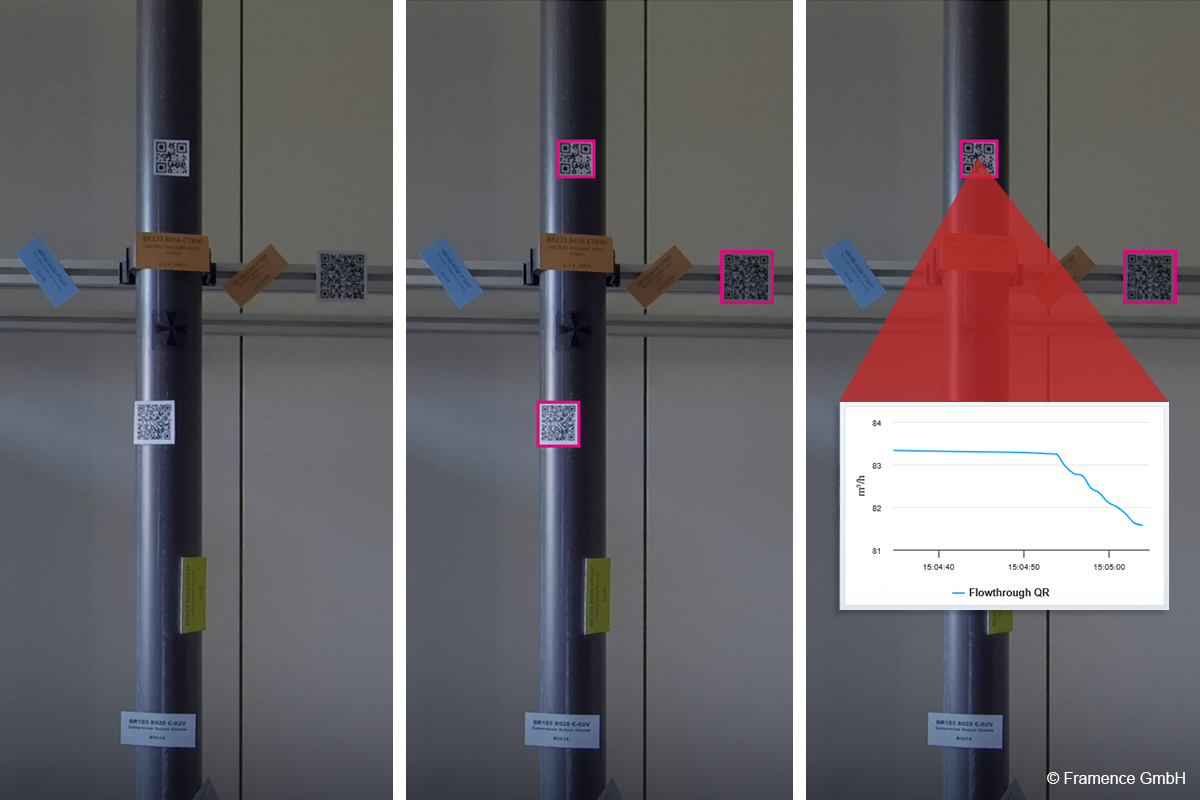

This is exactly where intelligent software applications come in: Their technology automatically recognises barcodes, QR codes and other tags using OCR (Optical Character Recognition), links them with the relevant information from connected data sources and integrates them directly into the system’s digital twin. And it does so automatically and without any manual intervention.

As soon as a code appears in the digital twin – for example through a new photo or an update – the application identifies it, retrieves the associated data and makes it available in context. The technician can thus access all information directly in the digital model:

- Maintenance histories,

- technical documentation,

- spare parts lists,

- live data.

One click is all it takes to make all of this available as if by magic.

In practice: from alarm to solution in seconds

In practice, it looks like this: A sensor reports a fault, such as a flow rate that is too low. The technician opens the software on his tablet, locates the affected sensor in the digital twin and clicks on the corresponding QR code. All relevant information immediately appears on the screen. No need to change location, no manual scanning, no database searches.

The added value: efficiency, transparency, availability

Automatic code recognition not only brings benefits for maintenance personnel. Companies also benefit on several levels at the same time:

- Reduced downtime thanks to faster fault diagnosis and rectification.

- Higher data quality thanks to automated linking and updating.

- More efficient processes thanks to the elimination of manual work steps.

- Better basis for decision-making thanks to complete and up-to-date information.

In an environment with thousands of assets, automating the linking of information is a decisive step towards a sustainable maintenance strategy. Sophisticated solutions with OCR and digital twins are the means of choice here.

Picture: Framence GmbH